Combination of a 480 W hot-gas source with a vacuum pen for manual reworking of circuit boards.

ReworkPerfect solutions for the entire range of applications.

Martin offers specialized equipment for the entire range of qualifiable rework processes. With the help of OPTIONAL TOOLS and the MINIOVEN 05, it is possible to prepare various component shapes for the process. Precise soldering profiles are our core competence. With our products, we guarantee perfect solutions, resource-conserving processes and reproducible results.

DevicesOur Rework devices.

High-performance 2,000 W IR under-heating system for hand soldering or preheating of medium-sized circuit boards.

Compact 500 W IR under-heating system perfectly suitable for preheating and handling small circuit boards.

Efficient 700 W contact-heat underheater for reworking small circuit boards and components.

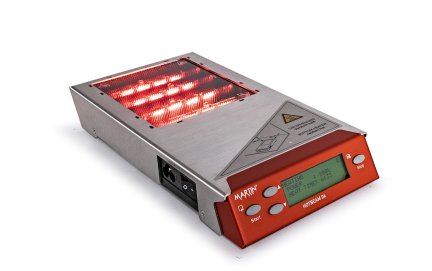

Compact hybrid device for reball and reflow processes on BGA, CSP and QFN components at the best temperature distribution.

TechnologiesOur Rework technologies for optimal results.

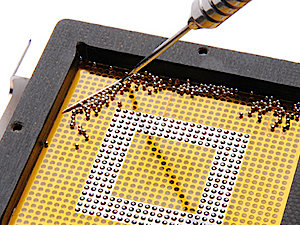

The pre-bumping process can be easily and safely performed with MARTIN's pre-bumping tools. These have been specially developed for use with the MINIOVEN.

VideosProduct- und application videos.

Reballing with the Minioven cuts cost and lead time by not outsourcing the product.

The Minioven offers a compact, fast, simple and economical solution for pre-bumping of QFNs.

Chip Underfill on a Puma pick-and-place machine with integrated dispensing

Essemtec AG, Aesch/LU, Switzerland